REGV - THREAD ROLLING MACHINES WITH STUD FEEDING UNIT

REGV - THREAD ROLLING MACHINES WITH STUD FEEDING UNITThread rolling machines with stud feeding units are essential in a variety of industries where safe and precise manufacturing of threaded studs is required. They help improve production efficiency, product quality and safety in various industrial applications.

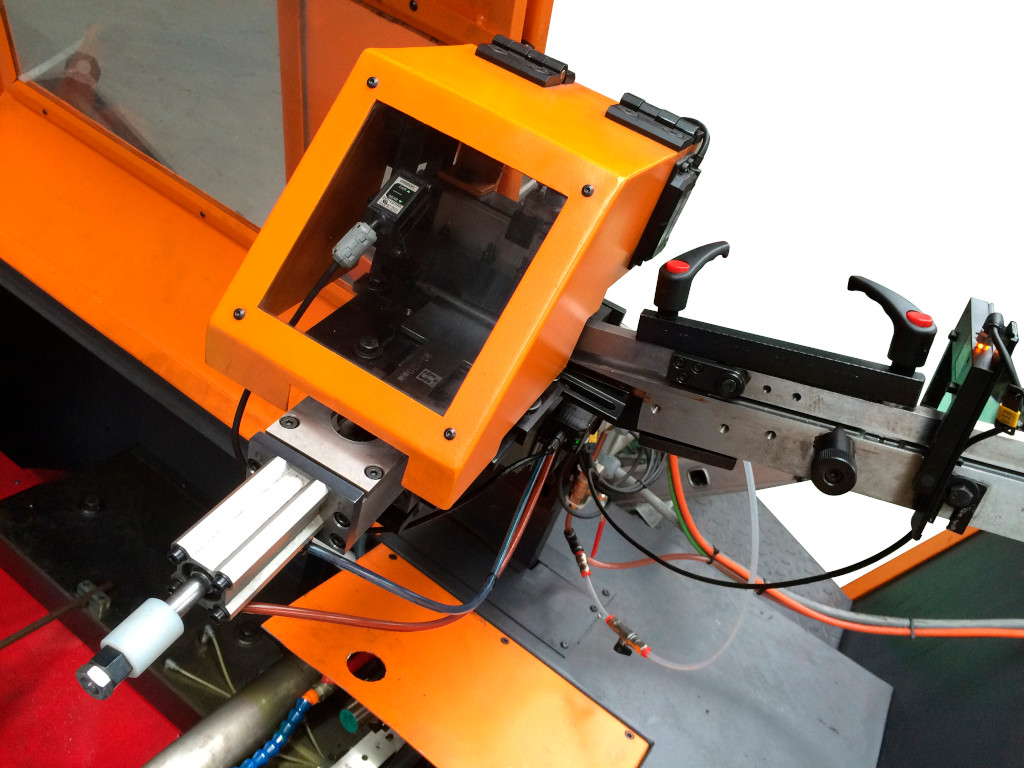

At Saspi we have a wide range of threading machines and second operation machines, specifically we have REGV, a thread rolling machine with stud feeding unit that, thanks to the use of cutting-edge technology, allows a great improvement in processes.

Would you like to discover more details about these machines? Continue reading!

What is a stud feed threading machine?

A Thread rolling machine with stud feeding unit is an industrial tool used in the manufacturing of products that require threads or profiles on headless parts.

These are the main features of a stud feeding threading machine:

- Automatic stud feeding: These machines are usually equipped with an automatic vertical feeding system that loads the studs or threaded rods into the proper position for the threading process. This reduces manual intervention and speeds up production.

- Threading unit: The machine is equipped with a threading unit that performs the main task of rolling threads on headless parts. This unit can be adjustable to fit different sizes and lengths of studs.

- Speed and torque control: To ensure threading quality and prevent damage to parts, these machines usually have adjustable speed and torque controls. This allows the machine to be adapted to different materials and clamping force requirements.

- Safety system: Threading machines usually have safety measures to protect operators. These systems may include emergency stop devices and protections to avoid accidents.

- Automation and programming: Some advanced machines can be programmed to thread different types of studs and automatically adjust the settings according to production needs. This makes it easier to adapt to changes in production.

- Storage and unloading of finished products: After the threading process is completed, the finished parts are usually automatically stored or unloaded into containers or conveyor belts for further processing or packaging.

In what industries are these threading machines used?

These machines are essential in industries such as automotive, construction and machinery manufacturing, where threaded studs are used in a variety of applications. They help increase production efficiency and ensure the consistency and quality of threaded connections.

Thread rolling machine with stud feeding units are used in a wide variety of industrial applications. Some of the main uses of these machines include:

- Automotive Industry: In the manufacturing of cars, trucks and other vehicles, studs are used to assemble various vehicle parts such as the engine, transmission, suspension systems and other components. This ensures secure and precise clamping of parts, which is essential for vehicle safety and performance.

- Construction industry: In construction projects, studs are used to connect beams, columns, steel frames and other structural elements. This helps ensure the integrity and strength of the structures.

- Machinery Manufacturing: In the production of industrial machinery and equipment, these elements are used to assemble critical components, such as shafts, gears, and drive systems. Precision in threading is essential for the proper functioning of the machinery.

- Energy industry: In the production and maintenance of power plants, power stations and related equipment, studs are used to connect pipes, valves and components essential for fluid flow and power generation.

- Railway industry: In the manufacturing and maintenance of rolling stock and railway tracks, they are used to join critical railway components such as rails, sleepers and suspension systems.

- General Manufacturing Industry: Stud threading machines are essential in the production of a wide range of products, these parts are used in everything from appliances to furniture and electronic equipment. They are used to assemble components and ensure the durability and integrity of the final products.

What advantages do Saspi stud feeding threading machines have?

Our REGV machine incorporates a feeding system for headless parts to a threading machine, highlighting the following:

• Improves productivity and reduces downtime.

• Ensures precision in threading.

• Get tight, high-quality threads.

• Simple setup and operation.

Its versatile design and focus on innovation make it a valuable investment for companies looking to optimize their production processes and maintain high quality standards.

Do you want to know more details about this machine? Do not hesitate to contact us through our form or send us an email to saspi@saspi.es. We will be happy to find your best solution!