Innovative washer assembly system

Innovative washer assembly system

At SASPI we have an extensive experience offering threading solutions for the automotive industry.

What was the challenge?

The customer had a high demand for large bolts with washers. However, in conventional washer assembly systems, the longer the screw, the more difficult it is to insert the washer. Therefore, so that it can be carried out constantly and without stops, it is necessary to reduce the production speed.

On the other hand, in the event that a screw and a washer are not assembled in a conventional system, both must be discarded and therefore productivity is lost.

What we did?

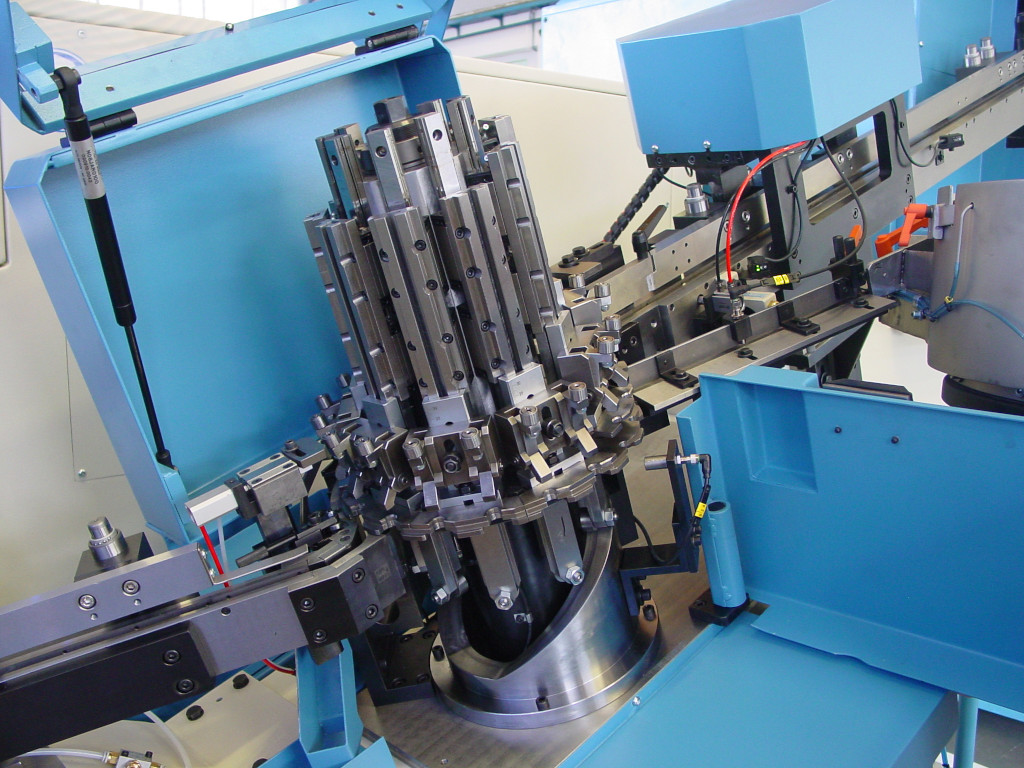

In order to solve the customer's challenges, we designed and created the WAS40, a new washer assembly system for our thread rolling machines, which regardless of the size of the screw, can run at high speed.

In addition, another feature of this system is that it allows the washerless screws to return to the assembly point, and therefore avoid reducing productivity if they were discarded.

This washer driver includes its own feeding system and can be removed motorized to thread screws without washers.

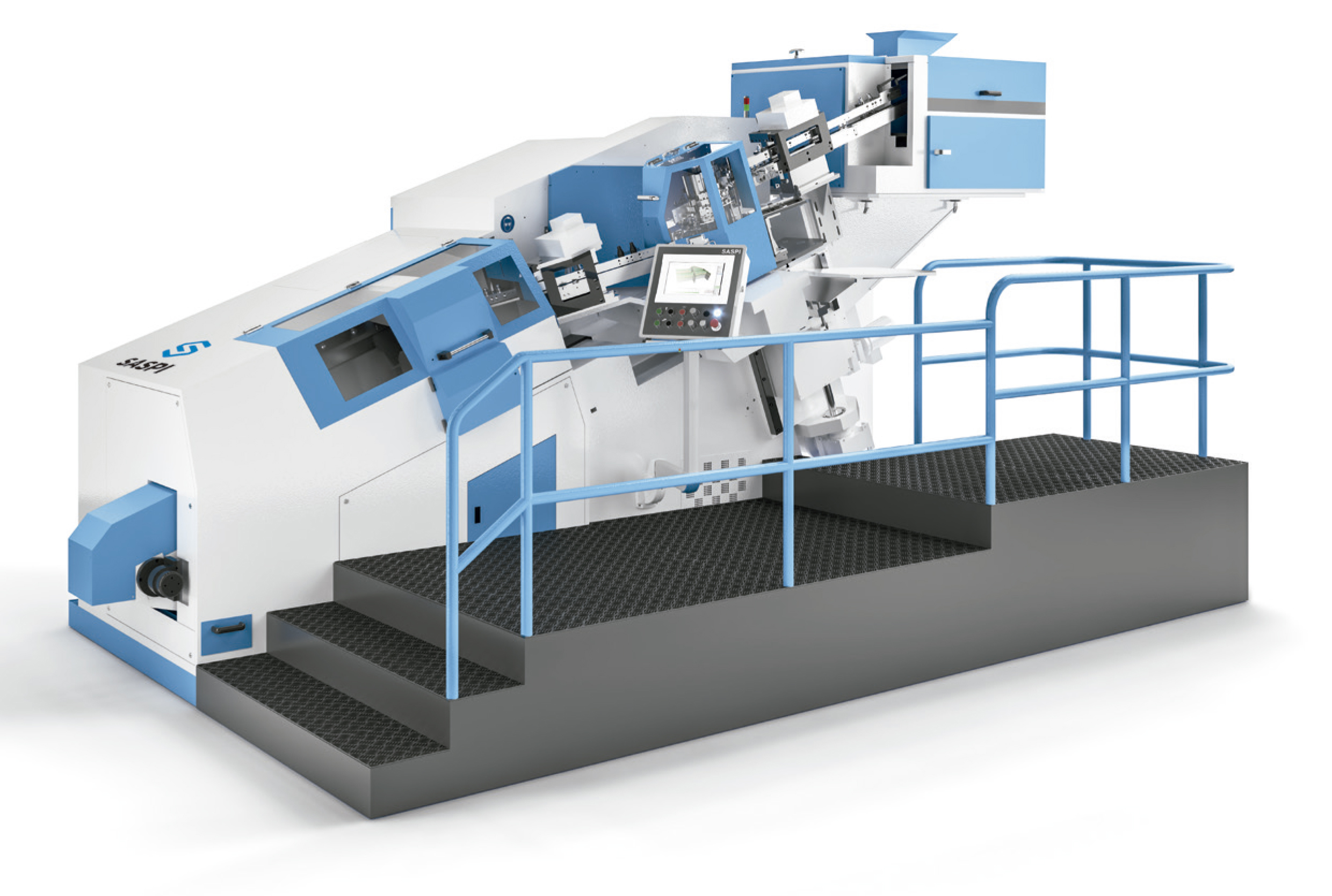

Washer assembly system Thread rolling Machine with Washer Incorporator

What have we achieved?

- Ensure that the client can cope with the high demand.

- Design and create an innovative solution.

- Improved process productivity.

- Customer satisfaction.

At SASPI we focus on the needs of each client, with the aim of providing the best tailored solution for each challenge that is proposed to us. Tell us about your case and our team of experts will analyze your case to offer you the best solution.