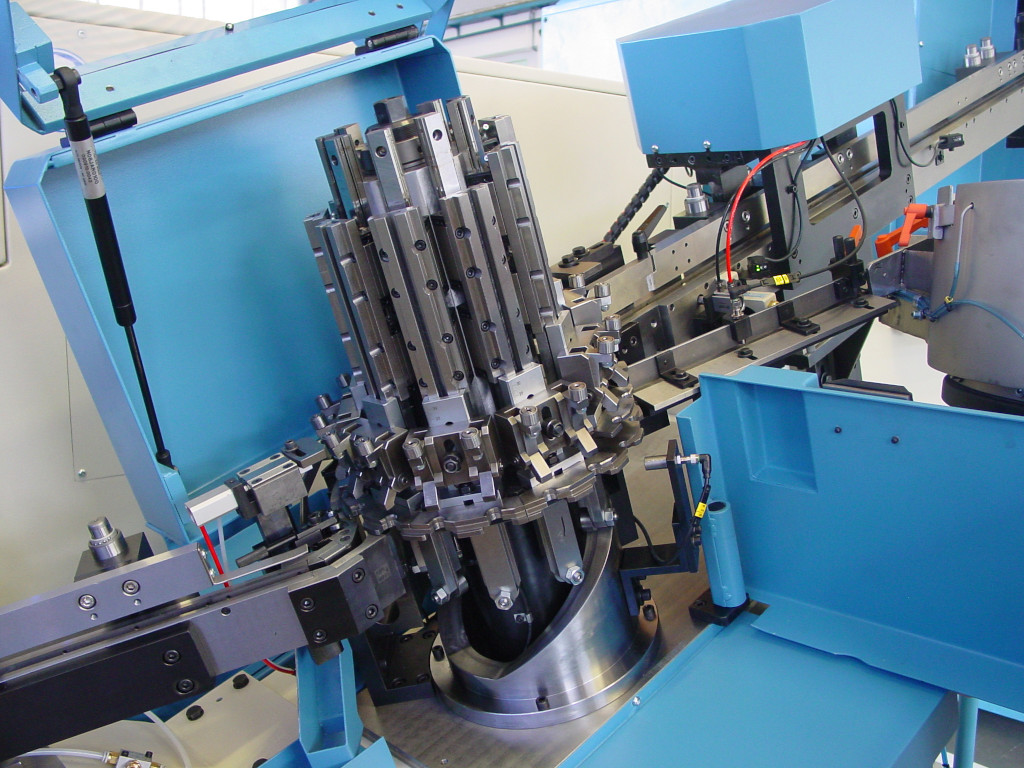

GV+WA Thread rolling machines with washer assembly units

GV+WA Thread rolling machines with washer assembly unitsThread rolling machines with washer assembly units allow increasing the flexibility of threading processes. At Saspi we have GV+WA, threading machines with washer assembly systems created with the best quality materials and using the latest in technology and innovation. Do you want to discover more about this type of machines? We will tell you!

What is a thread rolling machine with washer assembly system?

A thread rolling machine is a tool or equipment used to roll threads or different profiles in metallic materials. These machines are typically automatic and are used in a variety of industrial and manufacturing applications.

Incorporating washers into a threading machine refers to the machine's ability to automatically insert washers into the threading process. Typically, washers are thin, flat pieces with a hole in the center that are used to distribute the load evenly on a threaded connection and prevent damage to the surface of the material. Automatic addition of washers can improve the efficiency of the assembly process and ensure washers are placed correctly on each threaded connection.

In what area are these machines used?

Threading machines with washer assembly units are commonly used in the fastener industry to roll threads and at the same time incorporate washers in the threaded connections. This is typically done in assembly operations to ensure washers are properly positioned on threaded joints, which can improve the security and integrity of the connection.

They are used in a variety of industries including automotive, appliance industry, construction and others where threaded connections with washers are required to ensure a secure and durable joint.

What are the characteristics of thread rolling machines with washer assembly units?

Some features of our GV+WA machines may include:

- Automatic feeding of washers: The machine is equipped with a system that automatically feeds washers to the work area.

- Automatic threading: The machine creates threads automatically in the material, through rolling.

- Incorporation of washer in the process: The machine is designed to insert the washer into the part just before creating the threads.

- Error detection systems: Some machines may be equipped with sensors or detection systems to identify problems in the process and stop operation if necessary.

- Automation and programming: Many modern machines allow programming to adapt to different sizes and types of materials.

- Safety: They must have safety measures to protect operators and avoid injuries during operation.

What advantages does Saspi's GV+WA have?

The GV+WA are a series of machines that incorporate a system to assemble washers into the pieces before threading. They are designed to automate the threading process and insertion of washers, which can increase production efficiency and reduce the possibility of human error.

Saspi threading machines meet the production needs of modern businesses, enabling rapid response to daily changing market demands, using the latest in technology.

Are you interested in purchasing or learning more information about our GV+WA threading machines? You can contact our team through the form on our website or by sending an email to our email saspi@saspi.es.

We will provide you with specific details about the available models, their capabilities, and customization options based on your specific needs.