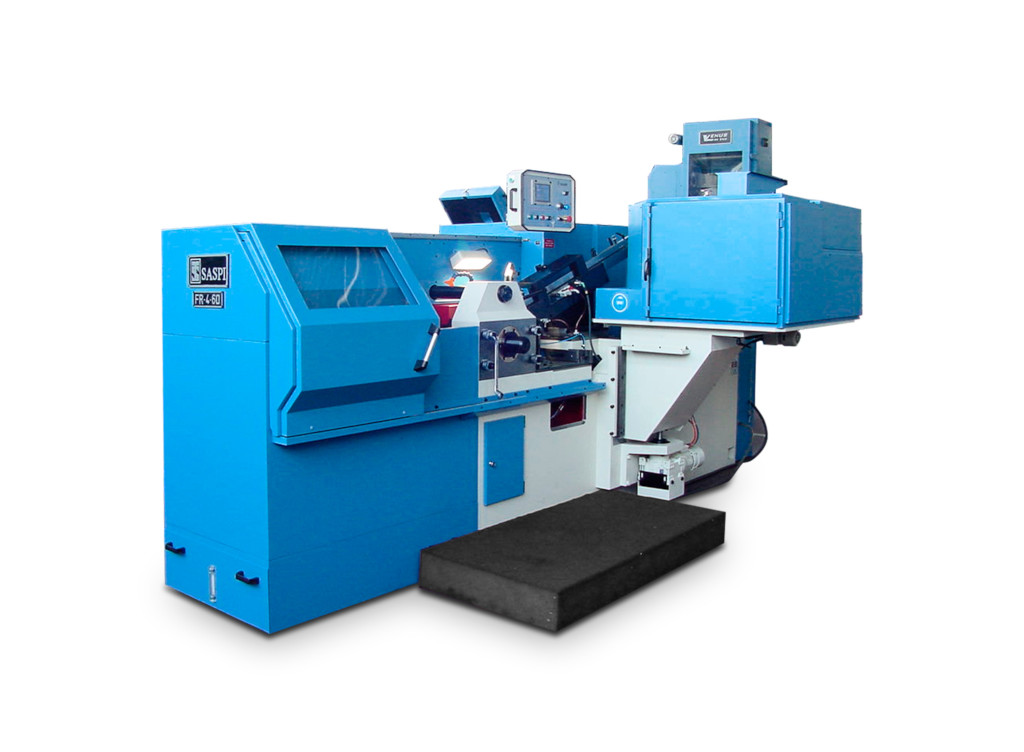

FR – Our form roller

FR – Our form rollerAt Saspi we have long-stroke thread forming machine that have been specifically designed for the manufacturing and shaping of complex parts. We tell you all the details in this article.

What is a form rolling machine?

A thread forming machine is a machine used in industry to form complex threads or profiles in a single pass. This machine is used to create threads, knurling, ringing, grooving, etc. on different types of parts.

The forming threader works by applying progressive force to deform the material and create the desired shape. In addition to making complex profiles, the forming threader is used to thread hollow pieces or soft materials since it can exert pressure in a more progressive way.

These machines are widely used in the manufacturing industry, where the production of parts with precise and consistent threads is required. Thread forming machines can be operated manually or automated, depending on the requirements and scale of production.

It is important to follow safety instructions and guidelines when using a thread forming machine as it involves the use of machinery that can pose risks if not handled properly. Additionally, it is recommended to use personal protective equipment, such as safety glasses and gloves, when operating a thread forming machine.

Use of thread forming machines

Thread forming machines are used in a variety of industrial applications where the creation of complex threads in different types of materials is required. Some examples of use of forming threaders include:

- Construction industry

- Automotive industry

- Aerospace industry

In general, thread forming machines are used in any industry that requires the manufacturing of parts with multiple profiles, as they offer an efficient and precise way to create these types of characteristics in materials. Its use helps to guarantee the quality, uniformity and resistance of the different profiles, which is essential for the functionality and safety of the final products.

What advantages does the FR - Forming Threading Machine from Saspi have?

All Saspi machines are designed to meet the production needs that companies currently have, offering a quick response to changes in the sector. Here are some of the main benefits our thread forming machine offers:

- Suitable for carrying out large deformations and multiple processes in a single pass.

- Meets the production needs of modern companies.

- Latest technology incorporated.

- More compact than a conventional threading machine: no great forces or inertia are needed, only long strokes of dies so that the piece has a high level of revolutions.

- Threading quality and precision.

- High performance in high demand productions.

Do you want to know more about this machine? You can consult our technical sheet, or if you need additional information, contact us through our form.